|

We were pretty excited about being able to do as much manufacturing as possible in the basement to keep costs low. The range of crazy things we did toward this goal includes punching out our own game tiles. From our last post we showed some of our laser cut tiles. When these tiles come out of the laser cutter, they have soot on them which you have to wipe off. As a general consumer, I'm pretty sure you've never bought a game with soot on it. To that end, enter in the die cutter! The dies used to cut board games are basically a cookie cutter, but for chipboard (dense heavy cardboard). Unlike a cookie cutter, the edge is made razor sharp, and you don't press with your hands, you use literally tons of force. We had a custom die made that would punch out one board game tile at a time and then we borrowed a 12 ton press from Justin (who is also one of our play testers). While some of the pieces came out fine, you can defective pieces on the right hand side of the final picture. Those types of defects happen when the die does not punch all the way through the material because of uneven force application. This isn't surpirsing because this was a hand powered 12 ton press. And we had no idea how much force we needed to apply to completely cut through the material. Plus, there was no way to measure how much force we were applying to the material. Often times we would cut too hard (and punch through the cutting mat we put below). Or we would cut too soft, and have these leftover pieces. Additionally, you'll notice in that same picture that lining up the die with the correct spot on the sheet was quite difficult. What we learned from all this is that we need to leave the die cutting to the professionals. Companies like Print and Play will happily make you custom dies and punch pieces out for you by the thousands. If you just need one or two copies, stick with the laser cut ones from The Game Crafter and just clean them off. Don't do what we did and try to do this yourself.

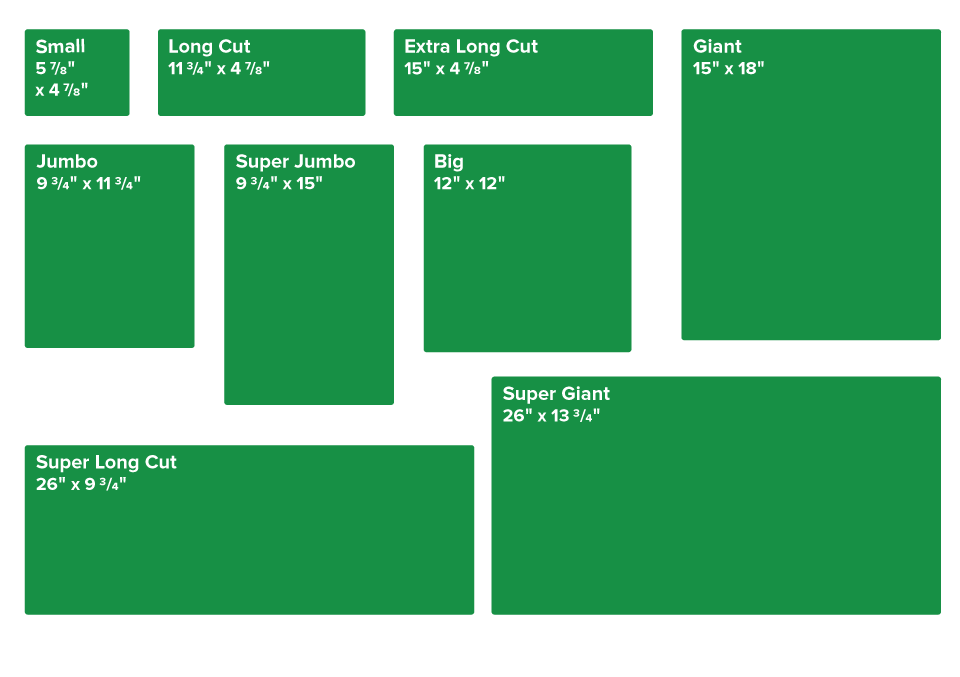

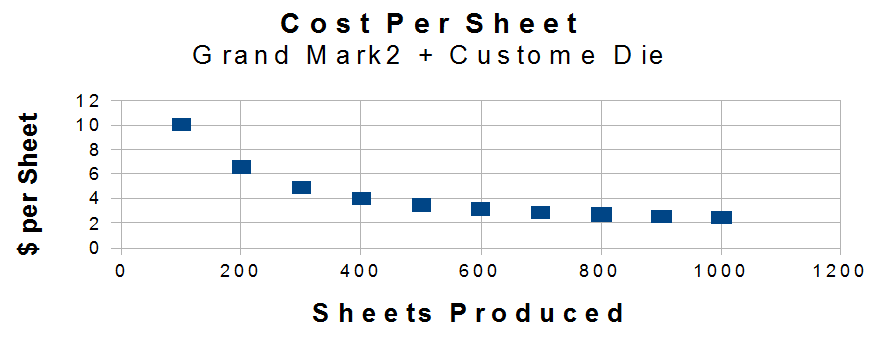

For those of you that are truly set on making as much as possible at home, there is one alternative that we didn't try: The $600 Grand Mark2 hand cranked die cutting machine. Supplied by Custom Shape Pros, this machine is capable of punching through chipboard. You will need both the machine AND a custom die to cut out your shapes. Once you have both the custom die ($250), and the Grand Mark2, you'll need to make your chipboard sheets with the graphics on them. We don't encourage you to make your own glue like we did previously, instead, get some stick paper. We talked to the people at Online Labels and for board games they suggested their Weatherproof Polyester 8.5 x 11" label. These are around $0.55 per sheet and you'll need to buy 100 sheets. The regular matte sheets only cost $0.18 per sheet but they will absorb water and get ruined the moment you have a party going.

Lastly, you'll need the actual chipboard sheets. I like the thickest chipboard money can buy. You can get 2.5mm chipboard in 8.5x11" from Kling Magnetics and they'll run you around $1 each. You can always buy thinner stuff as well, it will just get progressively more flimsy. Fun stats on the cost per sheet based on the setup prices we've listed above. You might be able to get these prices even lower if you are buying pallets of materials at a time!

4 Comments

3/9/2021 03:46:27 am

Wao for sharing how can we easily use <a href="https://impressionville.com/custom-die-cut-boxes/">die-cutting</a> packing for custom game pack. Can we use apparel boxes please guide me.? Thansk!

Reply

11/7/2022 05:01:50 pm

I loved that you shared that it's important to leave the die-cutting to the professionals. I'm hoping that I can talk to a professional about renting a die-cutter for my business. I definitely need to talk to a professional since I'm not sure what I need to do.

Reply

7/19/2023 06:12:32 pm

I appreciate your post thanks for the information. Some products require special packaging solutions the keep their worth and value intact.

Reply

Leave a Reply. |

AH Games

Tiny Independent Game Design and Publishers Archives

July 2023

Categories |

RSS Feed

RSS Feed